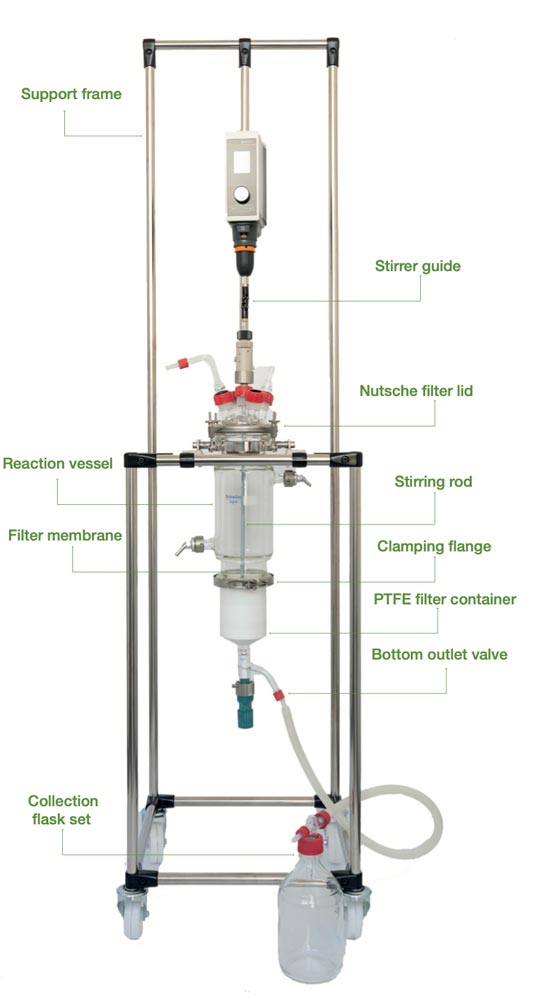

Nutsche Reactors: Synthesis and filtration in a single reactor

5 de August de 2024Recommendations for Nutsche Reactores of Scharlau by Afora

Obtaining high purity filtrates at a kilo lab scale is now much easier thanks to the introduction of Nutsche reactors. Nutsche reactors are designed to provide efficient and consistent filtration which optimises separation and purification processes in lab and small-scale production environments. Thanks to their advanced technology, Nutsche reactors are a guarantee of high-quality end products, facilitating research and industrial developments that require precision and reliability.

The Recommendations for Use and Installation of Scharlau Nutsche reactors by Afora offers clear, practical guidelines designed to maximise efficiency and safety when using the reactor; it is a comprehensive resource created to improve the user experience. By guaranteeing safety, optimising performance, facilitating maintenance and improving space and time efficiency, this document helps laboratories operate more efficiently and safely.

Nutsche Reactors: Use and installation

1. Place the glass body on the metal frame

2. Attach the filter holder to the PTFE container

3. Attach the filter to the PTFE filter holder

4. Place the sealing gasket on the PTFE filter holder

5. Attach the PTFE container to the Nutsche filter body

6. Close the clamping flange and ensure that the Nutsche body and the PTFE container are connected

7. Connect the drain cock to the collection flask

8. Install the collection flask assembly

9. Place the sealing gasket in the body of the Nutsche filter reactor

10. Insert the stirring rod in the reactor body

11. Position the lid on the reactor body with the retainer spring

12. Fit the retention ring on the retainer spring

13. Attach the lid to the body of the Nutsche filter reactor

14. Make sure that the lid is firmly attached to the Nutsche filter reactor’s body

15. Adjust the final height of the stirring rod in the reactor’s body

16. Connect the double cardan joint between the stirring rod and stirrer motor

Guarantees Safety

There are detailed instructions to help guide you through trouble-free installation and handling of Nutsche reactors. These guidelines are designed to ensure safe, risk-free operation, thereby creating a safe working environment for all users. Safety is a top priority, and these recommendations help minimise any risks associated with the equipment’s installation and operation.

Optimises Performance

We explain our recommendations for the efficient use of Nutsche reactors to maximise their performance and extend their useful life. By following these guidelines, users can be sure that their reactors are operating at maximum capacity, thus optimising resources and improving laboratory productivity. It is worth nothing that Nutsche reactors allow synthesis and filtration in the same reactor, which simplifies processes and reduces sample handling time. This dual capacity not only introduces significant time savings, but also achieves higher degrees of filtration purity by minimising exposure to external contaminants.

Facilitates Maintenance

This section includes some preventive and corrective maintenance tips so that users can proactively detect and resolve any problems. This approach results in easier, more efficient maintenance, which subsequently reduces downtime and increases equipment durability. The equipment is simple to prepare and maintain thanks to the easy-open flange connecting the filter and filter holder.

High-Quality Materials

Nutsche reactors are made of borosilicate glass 3.3, known for its high chemical and thermal resistance. This type of glass provides excellent durability and safety even in the most demanding working conditions, providing laboratories with a robust, reliable tool for their processes.

Efficiency in Space and Time

The compact design of Nutsche reactors offers significant space savings, making them ideal for laboratories with limited space. Furthermore, the ability to synthesise and filter in a single reactor, coupled with easy maintenance, results in time savings through faster, more efficient laboratory operations. The integration of functions ensures high-purity filtration processes and a more streamlined, efficient workflow.